Email Us

What Factors Determine the Fuel Efficiency of a Gasoline Generator?

Fuel efficiency is a critical factor when choosing a gasoline generator, as it directly impacts operating costs and environmental impact. Understanding the key factors influencing fuel efficiency can help users optimize generator performance and reduce fuel consumption. This article explores the major elements that determine the fuel efficiency of a gasoline generator.

1. Engine Size and Load Capacity

The engine size and the load it powers play a crucial role in fuel efficiency. A generator operating at or near its rated load typically runs more efficiently than one running at a low load. Oversized generators consume more fuel than necessary when underloaded, while undersized generators struggle to meet demand, leading to inefficiencies.

2. Generator Load Management

Efficient load management ensures that the generator runs at optimal capacity. Running a generator at low loads for extended periods results in incomplete fuel combustion, increased wear, and lower efficiency. Balancing the load with demand optimizes fuel consumption.

3. Fuel Type and Quality

Using high-quality gasoline with the correct octane rating improves combustion efficiency, reducing fuel wastage and emissions. Contaminated or low-grade fuel can cause incomplete combustion, leading to deposits and reduced efficiency.

4. Engine Maintenance

Regular maintenance, including oil changes, air filter replacements, and spark plug inspections, ensures the generator operates efficiently. A well-maintained engine experiences less friction and better combustion, leading to improved fuel efficiency.

5. Generator Technology and Efficiency Features

Modern generators incorporate technologies such as:

- Inverter Technology: Adjusts engine speed based on demand, reducing fuel consumption.

- Automatic Throttle Control: Modulates the engine speed to match load requirements.

- Fuel Injection Systems: Provide precise fuel delivery for better efficiency compared to carbureted models.

6. Operating Conditions and Altitude

Environmental factors such as temperature, humidity, and altitude impact fuel efficiency. High altitudes reduce oxygen levels, leading to inefficient combustion unless the generator is tuned accordingly. Extreme temperatures can also affect engine performance.

7. Proper Use and Best Practices

To maximize fuel efficiency:

- Avoid running the generator at very low loads.

- Perform routine maintenance and use high-quality fuel.

- Use an energy management system to distribute load effectively.

- Keep the generator in a well-ventilated area to ensure proper cooling.

Conclusion

Several factors influence the fuel efficiency of a gasoline generator, including engine size, load management, fuel quality, maintenance, and technology. By understanding these elements and implementing best practices, users can optimize generator performance, reduce fuel costs, and minimize environmental impact.

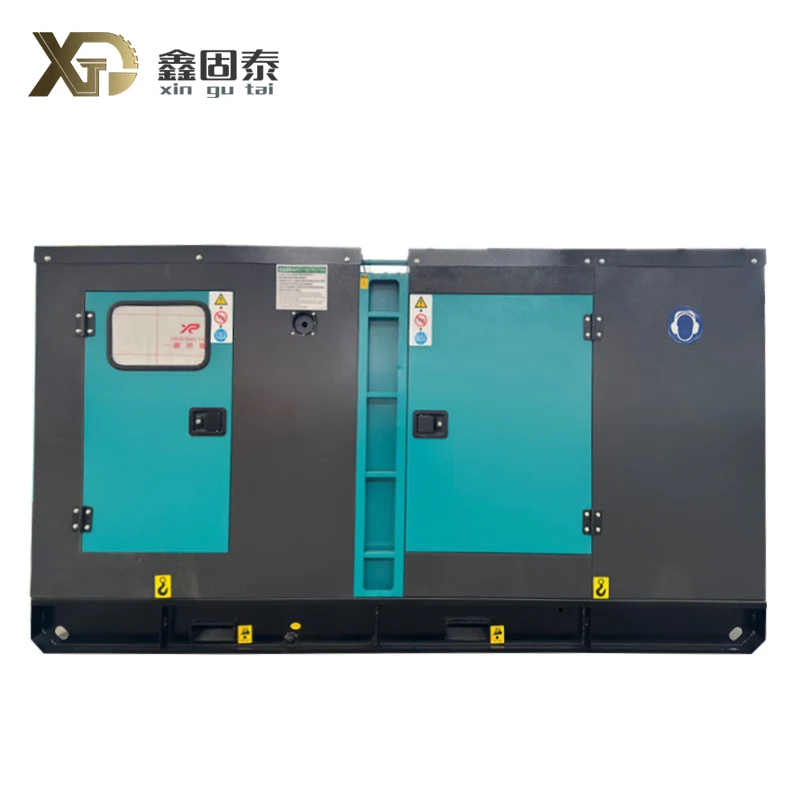

Gutai Machinery is a professional Gasoline Generator manufacturer and supplier in China. You are welcome to our factory.isit our website at www.xgtgen.com to learn more about our products. For inquiries, you can reach us at xueliqin@qzgtjx.com.

- Characteristics of Yuchai generator set.

- Maintenance of 400KW diesel generator set.

- Advantages and functions of gasoline generator.

- How Can Diesel Generator Sets Meet Your Power Needs Efficiently?

- Why Should You Choose a Low Noise Gasoline Generator for Reliable Power Supply?

- How Does a Small Gasoline Generator Provide Reliable Power Anywhere?

About Us

Contact Us

No. 55 Xingda Road, Huada Technology Entrepreneurship Park, Wan'an Street, Luojiang District, Quanzhou City

Copyright © 2024 Quanzhou Gutai Machinery Equipment Co., Ltd. All Rights Reserved.WEBSITE TECHNICAL SUPPORT: TIANYU NETWORK Jack Lin:+86-15559188336